The term “out-of-stock” (OOS) refers to a situation where the buyer cannot find the right product in the store. This may also include cases where the purchase did not take place due to lack of staff, inconsistency of the actual price with advertising or for other reasons under retailer responsibility. Let’s take a look at

According to statistics, traders around the world miss more than a trillion dollars in sales due to the lack of goods. The share of losses due to OOS depends on business specifics: if only every fifth customer remains without the right product in a pharmacy or grocery retail, then every third in electronics stores.

In any case, we are talking about lost profits. This creates additional pressure on the retail trade and forces it to look for ways to reduce losses. One of these methods is to increase the staff in the field of procurement, but for stores with tens or even thousands of commodity items, manual inventory management threatens losses. In addition, do not forget about frozen funds!

Automatic ordering systems are devoid of these disadvantages: by automatically analyzing the availability of goods and predicting consumer demand, they optimize logistics and, with a little manual intervention, minimize losses from OOS.

In this article, e-commerce experts from Andersen will tell you how customized solutions for the development of e-commerce help companies implement automatic ordering systems in their processes, providing a high level of customer service and remaining successful in the market.

Table of Contents

Causes and Consequences of OOS

The basis of any trading company activity is the purchase of goods for their further sale. Therefore, effective inventory management plays an important role for any retailer, whether it is a small corner shop or a large supermarket.

This work requires daily monitoring of stock balances, assortment analysis and decision-making about which goods and in what volume to order, how to deliver them to retail outlets and the store itself. At the same time, it is necessary to predict demand and take into account the limitations of suppliers. Every mistake threatens a shortage of goods and leads to empty shelves.

Several factors can cause this problem, but the main one is the incorrect calculation of the required reserves. Other possible causes of OOS include:

- high turnover of a specific product;

- delays in the delivery and distribution of goods;

- forecasting errors that exaggerate consumer demand;

- inefficiency of the product availability data collection system;

- poorly designed utility rooms where it is difficult to find goods;

- low quality of employees’ work or their quantitative deficit;

- problems related to promotions or the launch of a new product.

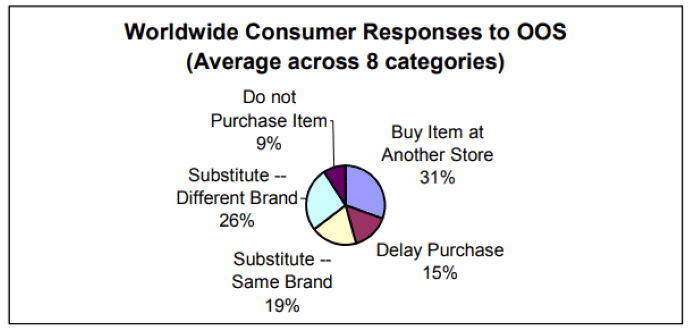

The scale of OOS depends on the stability of the marketing channel: a permanent assortment is not exposed to this risk, unlike new suppliers and products. In addition, OOS happens more often during “peak periods”: in large supermarkets, the jump in the indicator falls at the end of the week – Friday, Saturday and Sunday.

Seasonal goods may give additional spikes during the corresponding season. Thus, there are a small number of products that are not in stock that you can focus on: according to the study, for retailers in the United States, this is an average of 8%.

However, excess stocks are no less dangerous: they lead to an increase in storage costs, a reduction in storage capacity and working capital of the company. So, you will have to concentrate on selling the surplus.

Sometimes to the detriment of the purchase of in-demand goods. Of course, this leads to a drop in profits. In some cases, it is necessary to attract borrowed funds for current purchases and salary expenses, which additionally affects the profit margin.

If there are perishable products in the company’s assortment, thoughtless overstocking threatens irretrievable losses.

Thus, retailers have to constantly choose between optimizing logistics and warehouse costs, as well as meeting consumer demand. In addition, it must be predicted both at the level of individual SKU and in the context of each specific distribution center, warehouse or retail outlet.

With the increase in the assortment, this task requires more effort and time, going beyond the capabilities of one person and even an entire team of analysts. This is where automatic ordering systems come to the aid of retailers. They take over the management of balances and purchases, taking into account sales statistics and highly accurate demand forecasts.

Automatic Ordering and Other Digital Solutions

Retailers use various methods to track and eliminate the absence of goods in stock. These include the simplest methods of visual inspection of shelves in the trading floor, as well as software solutions based on MS Excel and reporting systems.

However, a wide range does not allow the effective use of even technological tools, if procurement decisions are still made “by eye”, since mistakes are inevitable. An automatic ordering system reduces the influence of the human factor, but it can cost a lot. Therefore, it is important to understand whether its use will pay off. Automatic ordering is required when:

- the assortment includes more than 1,000 SKU for retail or more than 500 SKU for distribution;

- purchases are mostly carried out manually, and the main responsibility for the result lies with several employees relying on their experience and expertise;

- when planning purchases, many factors have to be taken into account: short shelf-life and seasonality of goods, promotions, frequency of deliveries, various suppliers, substitute goods, delivery schedules, and so on;

- low efficiency of the warehouse, including shortage or overstocking, low turnover rates, and large proportion of expensive rare goods.

In these cases, the auto–order system is likely to pay off quickly. Also, it will give the company additional bonuses that allow you to save up to 30% of the procurement budget by reducing the cost of paying customers and storage.

In addition, the decrease in the OOS indicator keeps customers and increases their loyalty to the brands of both the retailer and suppliers. However, in some cases, you can make do with Excel capabilities, especially if there is no goods shortage in stock.

Please note that an automatic order is not needed if the assortment is small, the company works “to order” or does not keep systematic records of sales and product residues.

Independent Inventory Control

Despite the effectiveness of automatic order processing, small trading companies succeed thanks to the efforts of one employee who is well versed in business processes and knows Excel.

Although there are not many suppliers in the store and there is a stable demand for most of the products sold, a few spreadsheets are enough to quickly analyze which products need to be purchased and which should be excluded from the assortment.

But with the expansion of the product range or the opening of new outlets, this system usually fails. It becomes cumbersome and too dependent on one person’s decisions. In addition, manual processing of sales takes a lot of time.

Then companies often resort to writing their own accounting systems that take into account the specifics and scale of the business. However, an experienced developer is needed to create and maintain such a system.

But additional funds will have to be allocated for such a specialist. In addition, the company will need to build procurement processes in such a way that the system can make accurate forecasts. This will help to get rid of the main causes of OOS even without involving developers.

For example, you should enter a monthly or at least quarterly inventory of balances. This can be done cyclically, checking a small part of the nomenclature per day and noting each case of absence of goods in stock.

Statistics on OOS adjusted for trends and the economic situation allows you to determine how many units of a particular product you need to order and how often. As a rule, this already solves most problems.

However, you cannot do without working with the staff: there are often situations when the goods are in stock, but the employees do not have time or do not consider it necessary to replenish the shelves in the trading floor.

This may also include the introduction of planograms – visual prompts for employees arranging goods, as well as other ways to motivate staff. And only when the processes are established, and the most obvious reasons for out-of-stock are eliminated, you can think about connecting the auto-order system.

Implementation of the Automatic Ordering System

Connecting the company to an automatic procurement management system will cost several thousand dollars and will take from three months to a year and a half. The timing and cost depend on the complexity and smoothness of the processes, the number of articles and points of sale, the quality of the solution and some other factors.

This is not limited to the connection: you will also have to spend money on creating an IT infrastructure for the operation of the system and support. However, there are also compromise options on the market that allow the use of automatic ordering systems without expensive and time-consuming implementation. We mean cloud solutions.

Cloud technologies allow retailers to access inventory management products through a subscription model. In exchange for monthly payments, your business can use an automatic order without its own IT infrastructure and thereby quickly detect and eliminate cases of missing goods in stock.

In addition, in the process of using such a solution, the company gets access to other procurement analysis tools. It helps to make informed decisions quickly and reduce costs, increasing profits. Key decisions will no longer be tied to employees, so a subjective opinion will not prevent them from effectively performing their functions.

Another advantage of cloud services is the ability to use them to solve individual tasks without having to rebuild all business processes, as well as to test a specific system on your own data.

However, there is a downside to such flexibility: if for some reason a retailer cannot pay for the next month or quarter of using the platform, it loses its already familiar tools and, perhaps, it will have to hastily build business processes that have already managed to adapt to the auto-order system according to the old principles. This threatens both losses and dissatisfaction of the staff.

In general, distrust and even opposition of the staff is one of the main problems of automatic ordering systems introduction. Businesses often complain about the complexity or incorrectness of such solutions, but upon closer examination it turns out that the retailer either does not know how to use auto-order correctly, or simply does not trust it.

At best, this leads to even greater confusion in procurement, and at worst, to the emergence of a double–order system, when program forecasts can be compared with the results of independently made decisions or continue to be adjusted “by eye”. It is clear that there can be no question of any increase in the efficiency of procurement in this case.

Conclusion

The lack of goods in stock can be a really serious problem, but the use of automatic ordering systems will solve it. Procurement automation suggests that the business has already managed to build effective and consistent processes, while employees and owners are ready to entrust the program with making key decisions.

You can fix the OOS problem by finding a reliable partner such as Andersen to develop custom eCommerce software. Andersen specialists have 15 years of experience in the industry. Our portfolio contains examples of successful digital solutions for large financial magnates. Feel free to contact us if you need help developing custom software for digitizing your business.

Join The Logo Community

We hope these 6 Crucial Apps to Manage Your Finances have been helpful. If you would like more personal tips, advice, insights, and access to our community threads and other goodies, join me in our community.

You can comment directly on the posts and have a discussion with Andrew, the Founder of The Logo Creative.

*TIP – We recommend Skillshare to learn online. There are tons of classes for everything including graphic design, web design, marketing, branding and business-related courses. Get a free trial with our link and you won’t regret it Trust us!